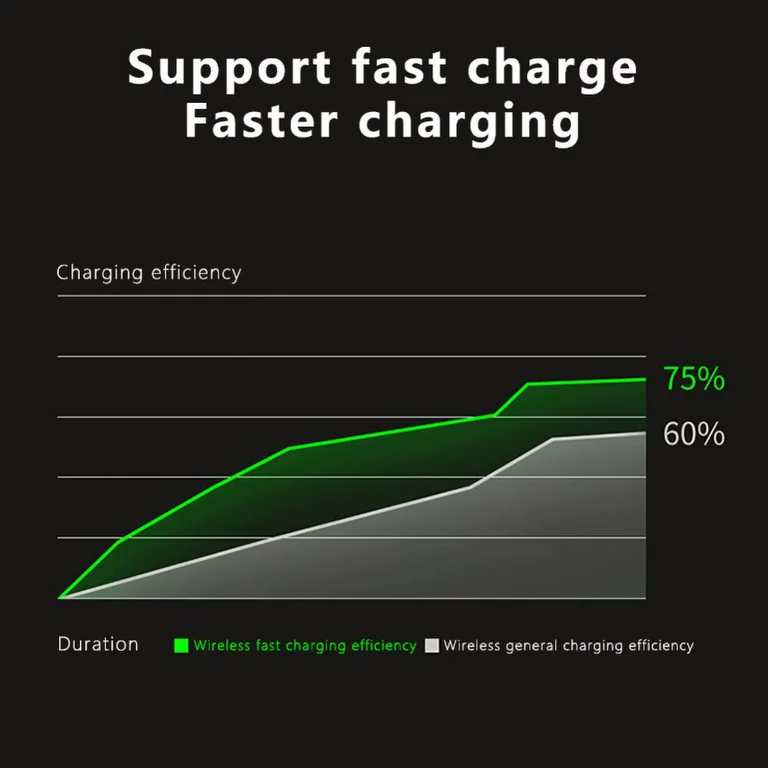

Charging efficiency refers to the ratio between the energy consumed by a lithium-ion battery during charging and the energy stored.

Improving charging efficiency can reduce energy loss and enhance discharge efficiency and lifespan.

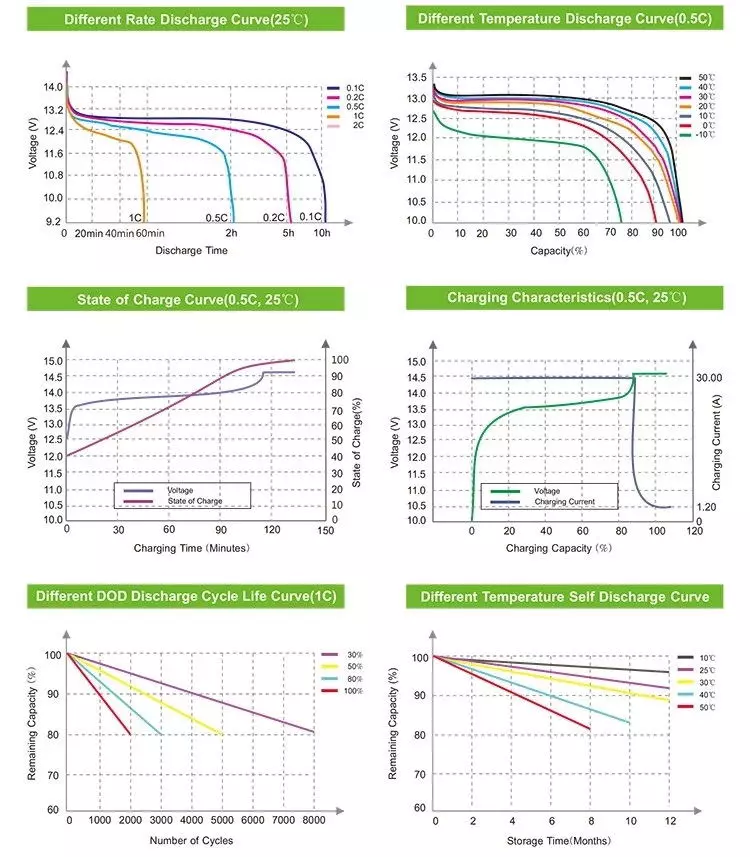

Before understanding the method of improving charging efficiency, let’s learn and analyze the charging and discharging of lithium batteries using a curve graph.

Lithium-ion Battery Charge and Discharge Curve Analysis

Charge and discharge curve analysis refers to the analysis, and research of the voltage and current changes, during the charging and discharging process of batteries or capacitors.

By analyzing the charge-discharge curve, you can gain insights into the performance and characteristics of the battery or capacitor.

This analysis lets you evaluate important parameters such as capacity, internal resistance, and cycle life. —- You can click on the orange text to learn more about the factors affecting battery cycle life.

The charge and discharge curve typically represents time. On the horizontal axis and voltage or current on the vertical axis.

During the charging process of the lithium-ion battery, the voltage gradually rises until it reaches the predetermined end-of-charge voltage.

During the discharge process, the voltage gradually decreases until it reaches the predetermined end-of-discharge voltage.

By observing the shape, slope, and change trend of the charge-discharge curve, several important analysis points can be identified.

Charging efficiency: Charging efficiency refers to the energy loss of the battery during the charging process.

By observing the slope and changing trend of the charging curve, one can evaluate the efficiency of the charging process.

The steeper the slope, the higher the charging efficiency.

Discharge characteristics: The discharge characteristics refer to the voltage change of the battery or capacitor during the discharge process.

By observing the slope and changing trend of the discharge curve, one can evaluate the discharge characteristics of the battery or capacitor.

The steeper the slope, the better the discharge characteristics.

Capacity Evaluation: The capacity of the battery or capacitor can be evaluated by observing the area under the charge-discharge curve. The larger the space, the greater the capacity.

Evaluation of Internal Resistance: The internal resistance of a battery or capacitor can be assessed by observing the variations in voltage and current in the charge and discharge curve.

The faster the voltage drops, the greater the change in current, indicating a higher internal resistance.

Cycle Life Evaluation: The cycle life of a battery or capacitor can be evaluated by observing the shape and trend of the charge-discharge curve.

If the charge-discharge curve changes minimally and the shape remains stable, it indicates a longer cycle life.

Charge-discharge curve analysis is an important method for evaluating the performance and characteristics of a battery or capacitor.

This analysis can assist in selecting an appropriate battery or capacitor and understanding its usage and lifespan.

Next, the expert team at PVMars will guide you in understanding—How to test the charging efficiency? How to improve it based on the test results?

Charging efficiency test:

Method 1: Use an electric energy meter or a power meter to measure the input energy and output energy during the charging process of the lithium-ion battery, and calculate charging efficiency.

Charging efficiency = output energy / input energy × 100%

Method 2: Use charge efficiency data from the Battery Management System (BMS), or Charge Controller to monitor and record.

Ways of improving the charging efficiency of lithium-ion batteries:

1- Choose a suitable charger (if in a solar or wind system, the controller and the UPS/Hybrid inverter are appropriate chargers):

Select a charger that meets the battery’s needs to ensure that the output power and voltage of the charger are stable, preventing energy loss and damaging the battery.

2- Control charging current and voltage: According to the charging characteristics and charging requirements of lithium-ion batteries, reasonably control charging current and voltage.

Avoid excessively high or low charging current and voltage, and improve charging efficiency.

3- Optimizing the charging algorithm, such as constant current charging, constant voltage charging, cutoff charging, etc., can lead to improvements in charging efficiency and speed.

4- To reduce energy loss and avoid excessive charging time, it’s important to control the charging time during the charging process. Within the PVMars energy storage system, a rigorous set of algorithms exists.

The controller and the inverter respectively control the charging and discharging voltage.

And current of the solar panel/wind generator, and is not allowed to exceed the setting specified by the lithium-ion battery.

5- During charging, regulate the temperature according to the battery’s temperature characteristics to improve charging efficiency and protect battery safety.

For instance, in BESS, we configure HVAC for temperature control to tightly control the impact of temperature on lithium-ion batteries.

To find out more about BESS and HVAC, click on the orange text if you are interested.

6- Optimization of charging interface and connection line:

Optimizing the design and choice of materials for the charging interface and connecting line can improve load efficiency and reduce resistance and energy loss.

7- Optimize the battery management system (BMS):

By enhancing the BMS design and algorithm, precise control and management of the charging process can be achieved, and charging efficiency can be enhanced.

Notice:

It is important to acknowledge that improving charging efficiency is a comprehensive issue.

The comprehensive consideration of multiple factors, such as lithium-ion battery characteristics, charger design, charging algorithm, and system optimization, is necessary.

In practical applications, it is recommended to select appropriate methods and measures to improve charging efficiency.

According to specific needs and conditions, combined with PVMars professional technical support and guidance.