If you want to know what configurations are contained in the PV Array BESS, it is enough to read this article. PVMARS has been focusing on photovoltaic energy storage technology for 17 years.

With the development and popularization of new energy sources such as photovoltaics, wind energy, and energy storage.

More and more people hope to combine them together to exert more than 100% power generation efficiency.

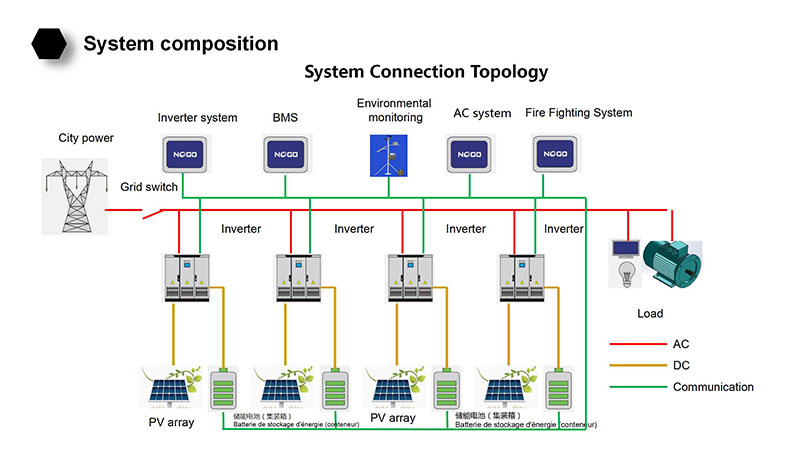

For example, the 2MW case also uses photovoltaics and energy storage to achieve a reliable and stable power supply.

So how is this power supply achieved? — Different configurations must cooperate to achieve this.

After 17 years of solar energy storage technology research by PVMARS, the following PV Array BESS configuration list is obtained.

- Solar panels

- Ground support/PV bracket

- PV combiner

- Power conversion system (PCS)

- Lithium battery system

- Battery management system (BMS)

- Power management system (PMS)

- Heating, ventilation, and air conditioning (HVAC)

- Dynamic environment monitoring system (controller cabinet)

- Fire suppression system

- Supervisory Control and data acquisition (SCADA)

- Energy management system (EMS)

- Ancillary equipment – Junction boxes, cabling, lighting, sensors, breakers

- Enclosure as container

This is the most complete solar panel array BESS configuration. If part of it is missing, the whole system may become unsafe or impossible to work with.

Next, let’s dive into what each configuration does and why you need them.

Photovoltaic matrix (Solar panels)

Since it is a power supply mode of photovoltaic + energy storage, solar panels must be the shining star.

PVMARS configures junction boxes and MC4 equally for different types of solar panels (PERC type, Half-cell type, and others).

Please refer to the figure below for the connection of solar panels through MC4. Pay attention to the positive and negative poles.

Ground support/PV bracket

If you want solar panels strong enough to absorb sunlight and generate electricity, you need PV brackets to support each solar panel.

For large-scale PV energy storage systems, there are generally hundreds or thousands of photovoltaic panels. Engineers will design the series-parallel connection of solar panels according to system parameters.

At the same time, the PV bracket is also used to separate and plan the distance between each group of photovoltaic arrays. This is to achieve the maximum power generation efficiency of each group of solar panels.

In addition to supporting and planning the solar panel array, ground support can also install a PV combiner on them.

PV combiner/DC lightning protection cabinet

In small solar energy storage systems, it is called a PV combiner.

In large-scale photovoltaic energy storage systems, its name varies, but its main function remains the same. It acts as a staging point for thousands of solar panels to find their homes.

It will be found in every group of the PV array. The PV combiner connects each group of solar panels in series.

It finally outputs 2 or even 4 groups of positive and negative wires, which follow a fixed route and travel straight to BESS.

In addition to stably transmitting solar direct current to BESS, the PV combiner also has built-in high voltage and lightning protection devices.

When thunderstorm season rolls around, it protects the panels at the expense of built-in lightning protection.

You only need to replace the new lightning protection device, and you can maintain the solar panel from lightning impact at a low cost.

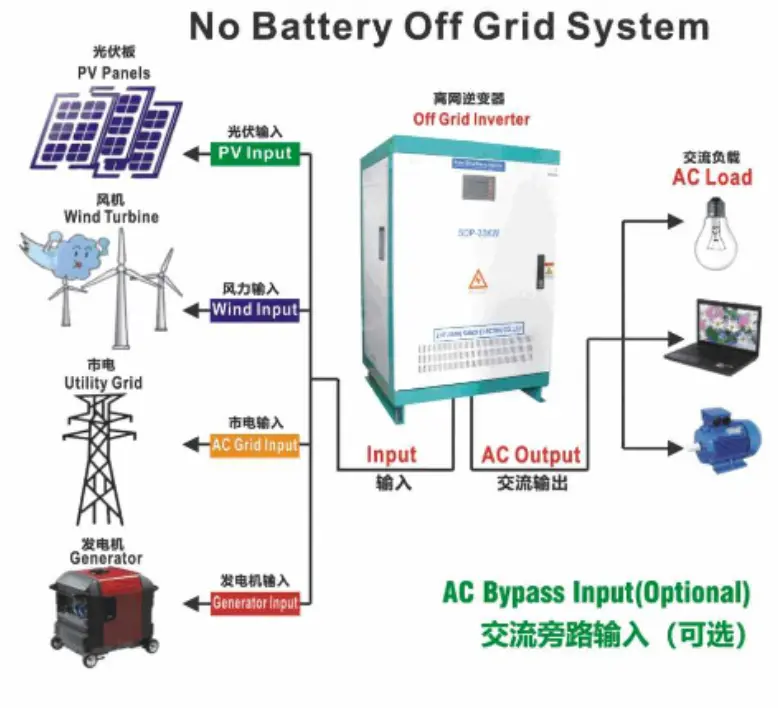

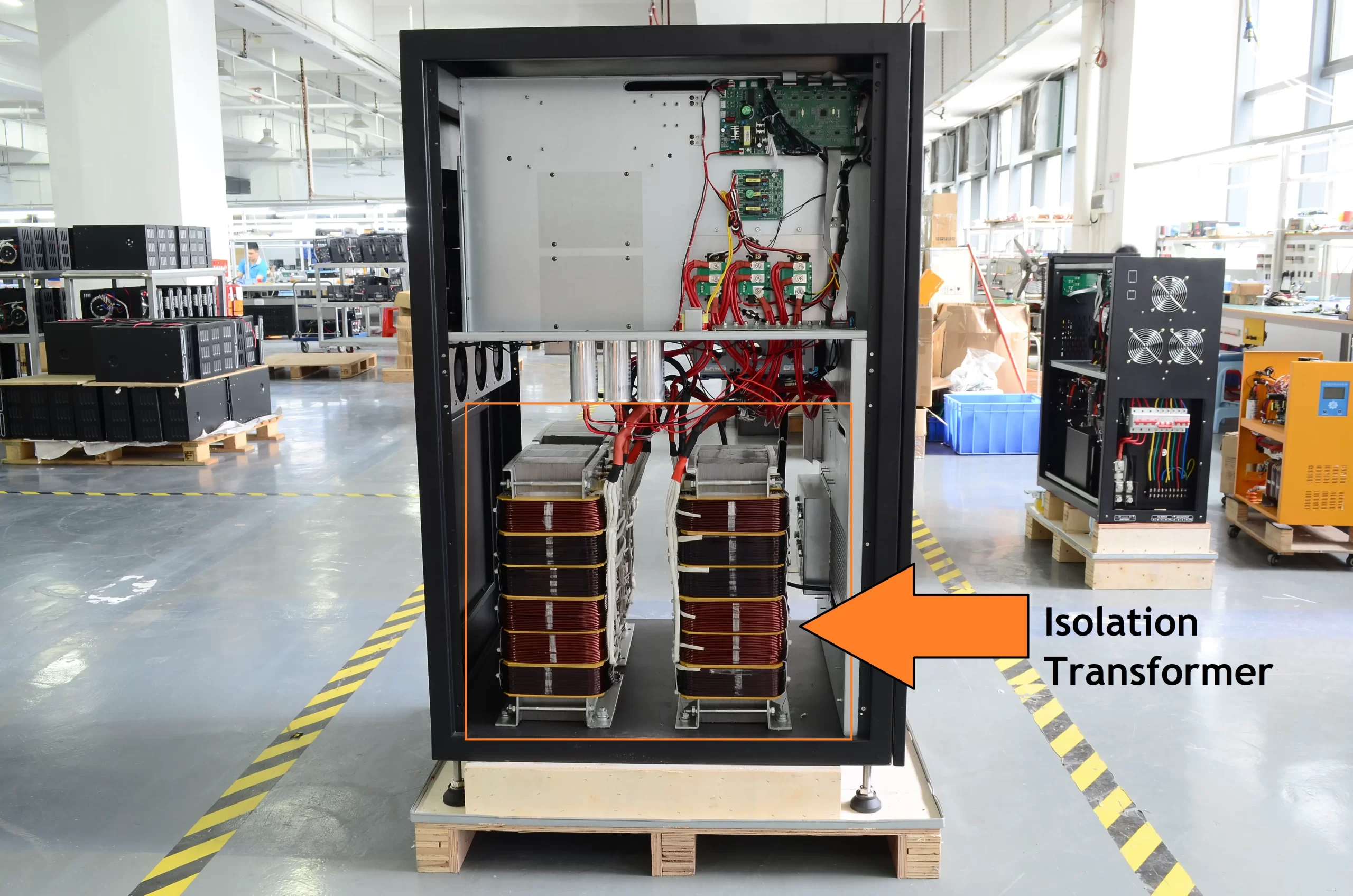

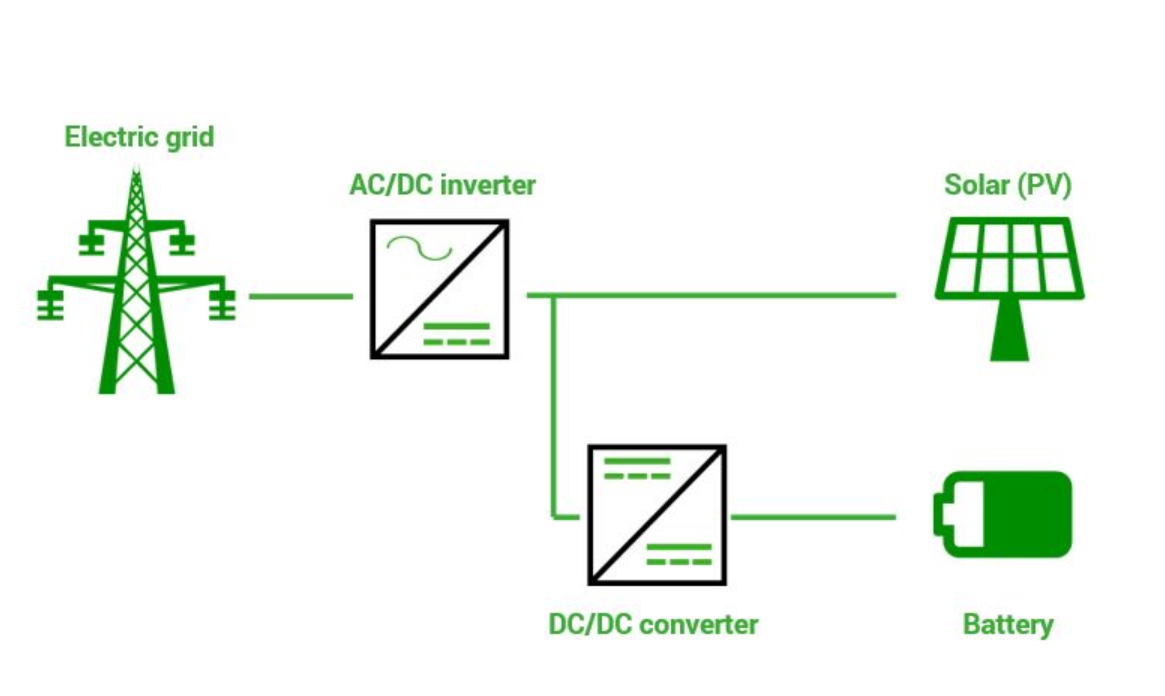

Power conversion system (PCS)

As mentioned earlier, the PV combiner transmits photovoltaic direct current to the BESS, then power passes through the PCS.

PCS includes bi-directional power control and an inverter with multiple charging/discharging modes. In a PV energy storage system, this inverter can be set to prioritize power supply to the load.

It can also supply solar power to the lithium battery.

If the local public utility grid is connected, PCS will also integrate the urban grid into the BESS to become a third power source (photovoltaic, lithium battery, urban grid).

Lithium battery system

Lithium batteries are currently the most popular type of rechargeable battery in the energy storage industry.

In the future, PVMARS will also provide flow batteries for BESS in addition to traditional gel batteries and lithium battery products.

Lithium batteries belong to the 9th category of dangerous goods. When transporting BESS, we must apply for UN3536 to allow import and export. For more information about lithium batteries, please click here.

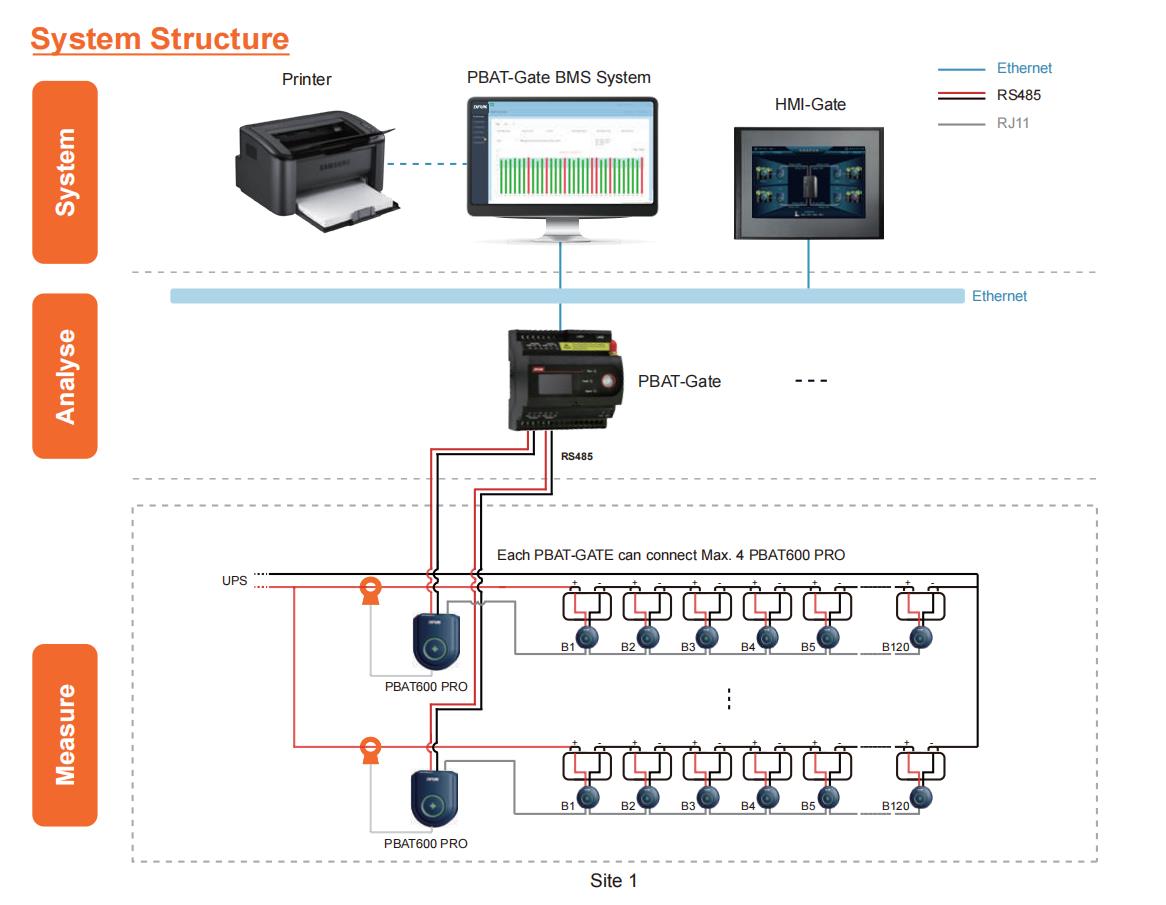

Battery management system (BMS)

Usually, a UPS is installed for real-time monitoring of the battery pack, and various battery values are transmitted to the SCADA system.

Supports SNMP, Modbus, TCP protocol – RESTful APIs, JSON, XML format – SMS/email alarms – 4G data upload.

This is intended to improve the safety of lithium batteries, maintain proper internal temperature, ensure proper SOC, and enhance battery life.

Power management system (PMS)

This is a device or group of devices that control electricity flow in a system.

In BESS, it controls the flow of electricity from the solar panel to the lithium battery, and from the battery to the load.

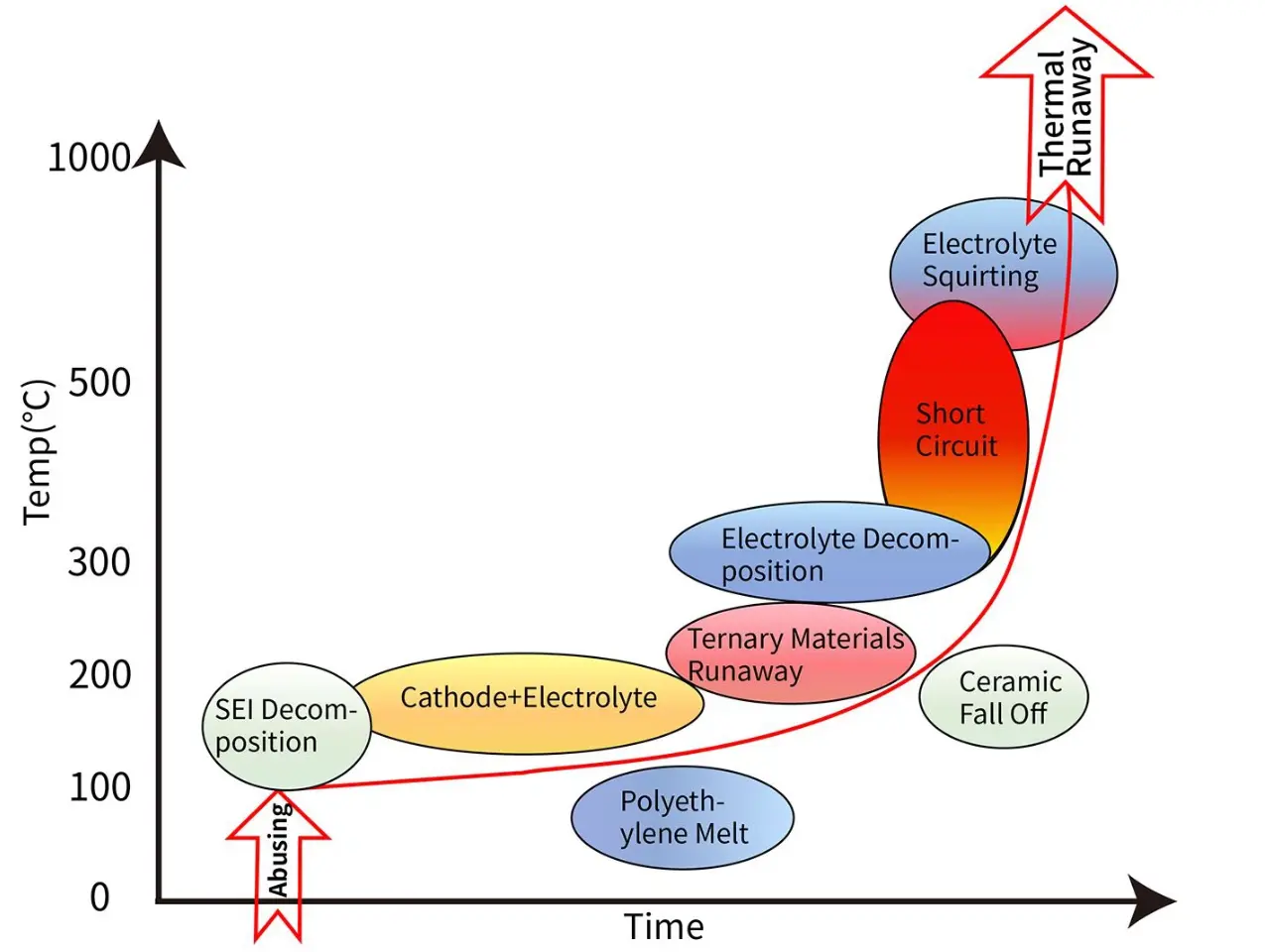

Heating, ventilation, and air conditioning (HVAC)

Whether in the hot Middle East, or cold Iceland. If you choose BESS, be sure to install HVAC.

In addition to heating, we will need to install other ventilation and air conditioning systems.

To dissipate heat generated by the lithium battery and PCS inside the BESS.

And avoid thermal runaway caused by the high temperature in the room, it will eventually result in a devastating explosion.

Dynamic environment monitoring system(Controller cabinet)

It is equivalent to adding a firewall, which is real-time video monitoring of all equipment inside the BESS.

For example HVAC, internal humidity (curve display), fire protection system, and intelligent control of BESS machine room access (providing security, anti-theft).

During 24-hour monitoring of multiple BESS operations, any abnormality will trigger an alarm, and technicians will be notified via dialing, SMS, email, and wireless modems.

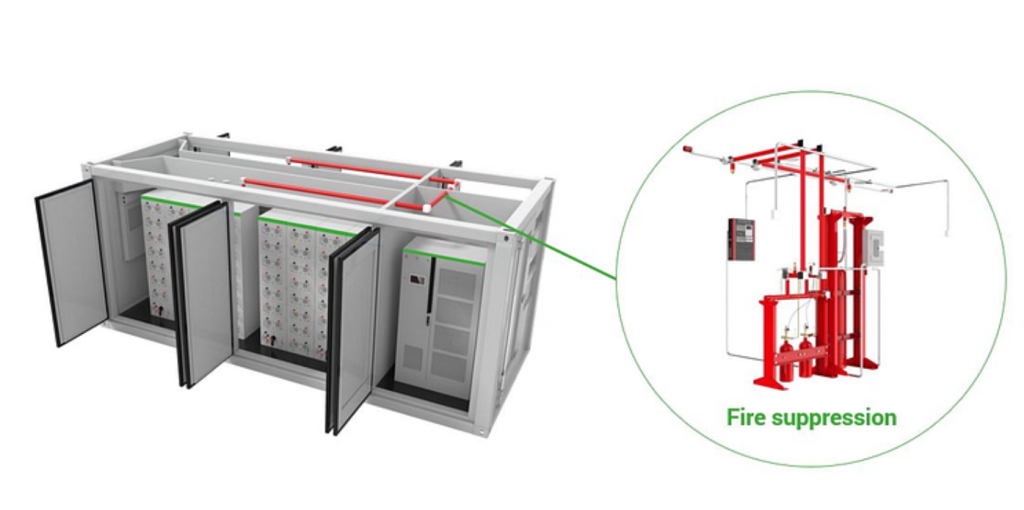

Fire suppression system

PVMARS’ fire suppression system has a variety of options, set based on different regions and people’s habits, including:

Water-based systems: These systems use water to extinguish fires. Water is an excellent conductor of electricity, so it can be dangerous to use in BESS where electrical arcing is possible.

Foam-based systems: These systems use foam to extinguish fires. Foam is less conductive than water, so it is safer to use in BESS where electrical arcing is risky.

Gas-based systems: These systems use gases, such as carbon dioxide or halogen, to extinguish fires. Gases extinguish fires very effectively, but they can harm people and the environment.

Aerosol-based systems: These systems use a fine mist of water or fire suppressant to extinguish fires. Aerosol systems are safe to use in BESS and effective at extinguishing fires.

The best type of fire suppression system for a BESS depends on the specific application.

In remote areas, water-based systems may be the best option, while in densely populated areas, aerosols would be the best option.

Supervisory Control and data acquisition (SCADA) Energy management system (EMS)

Both systems have the same practical purpose, monitoring and controlling remote equipment.

In the context of a BESS, SCADA can be used to monitor the state of the battery. It can also control the charging and discharging of the battery, and manage the flow of power from the battery to the grid.

SCADA systems typically consist of three main components:

A centralized controller that collects data from the BESS and sends commands to the battery.

Remote Terminal Units (RTUs), located at the BESS, collect data from the battery.

The communication link connects the RTU and the central controller.

PVMARS will customize the SCADA data platform suitable for them to view data according to different users’ needs.

So that users can concentrate on one software platform to view and monitor all equipment inside BESS.

Ancillary equipment - Junction boxes, cabling, lighting, sensors, breakers

It looks inconspicuous, but without them, a complete BESS set cannot be formed.

For example, breakers, if there is no control switch for it, the wires between the lithium battery and the PCS will be messy and there is a risk of explosion.

Therefore, when our team designs such a complex system, we will submit a satisfactory and safe solar energy storage solution to both parties.

This is done after controlling the details of the use environment, user needs, and equipment parameters.

The enclosure as a container

For the container appearance, our factory accepts OEM customization, and everything can be customized according to user needs.

In conclusion

Any inconspicuous small part may cause immeasurable losses.

PVMARS has been deeply involved in solar energy storage technology for 16 years.

It always cares about users’ feelings, and constantly seeks to develop new technologies to meet your needs for renewable energy PV arrays BESS.